SugarCane

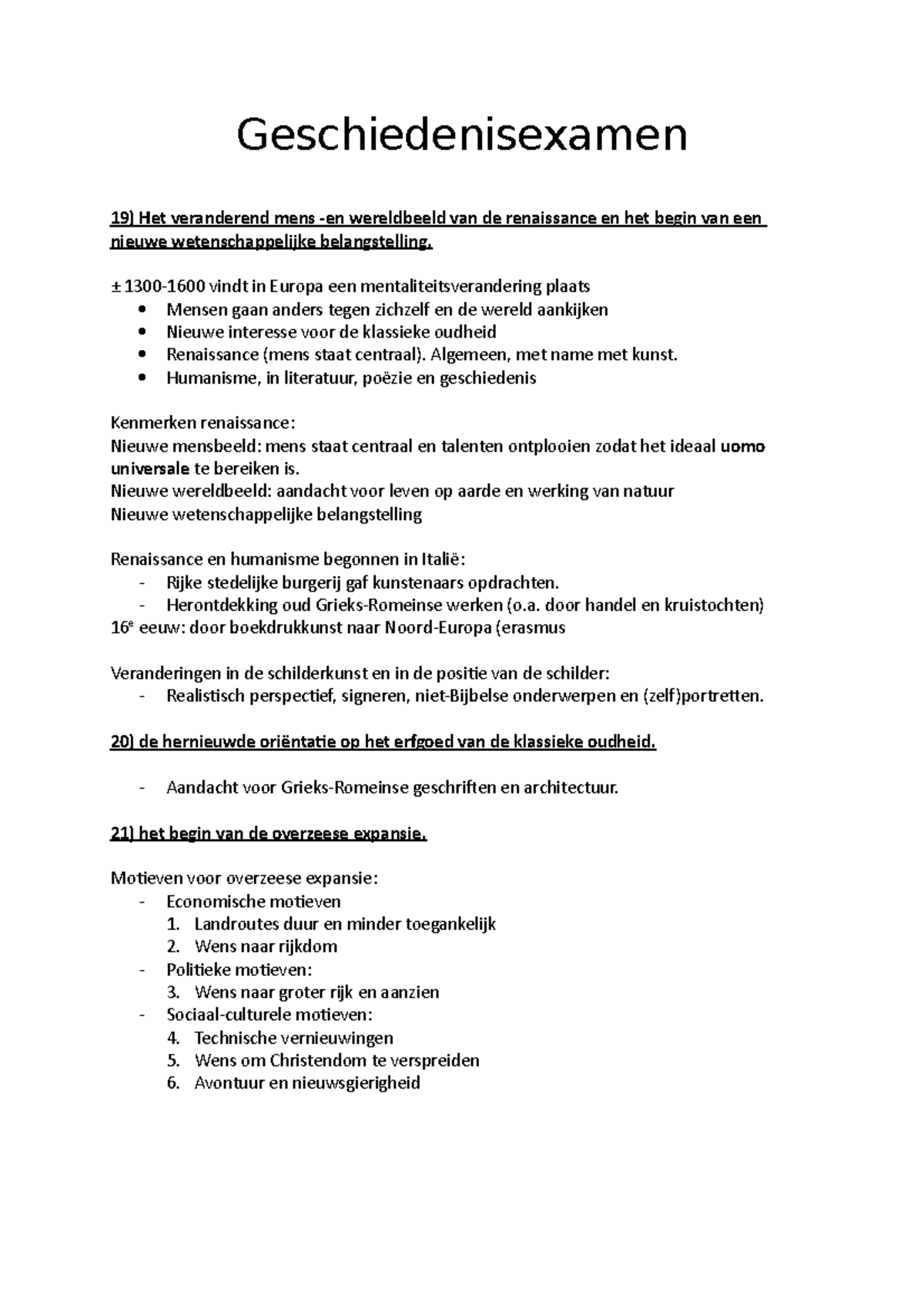

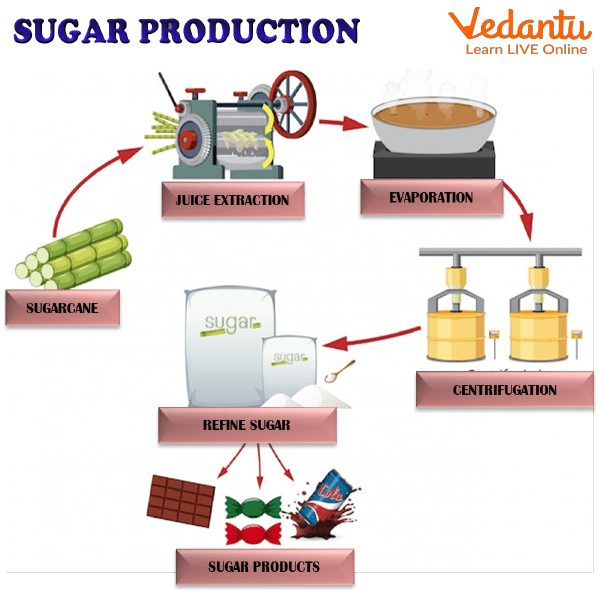

The first step in the sugar manufacturing process is the cleaning process. This process involves removing any dirt, debris, or other contaminants from raw sugar cane. Raw sugar cane is usually soaked in water and cleaned with a brush or other cleaning implements. After the cleaning process, the sugar cane is cut into smaller pieces.

Process flow diagram of sugar processing Download Scientific Diagram

Throughout the manufacturing process, sugar is tested for purity, sucrose content, proper pH balance, temperature, color and consistency. Monitoring of equipment and filtering materials ensures that they are working efficiently. Because it's 99.9% sucrose, refined sugar is one of the highest-quality products you can find at a grocery store..

A digram of sugar production Royalty Free Vector Image

This. process separates the sugar juice from the fibrous material, called bagasse. The sugar juice is pumped away for processing into raw sugar and the bagasse is recycled as a fuel for the mill boiler furnaces. Juice extracted from the crushing mills contains impurities which are removed by adding lime and heating the limed juice.

Sugar how is produced from cane? Eufic

What is Raw Sugar: Raw Sugar is produced from sugar cane or beet by an ordinary process known as the Defecation process. According to Peter Rein, raw sugar can be defined as "Brown sugar produced in a raw sugar mill generally destined for further processing to refined sugar". a) It is Unwashed centrifugal sugar with minimum polarization 96.5o .

Sugar Cane Process Flow Diagram

This Processing column describes the process by which sugar is harvested and processed.. of "How is it processed?" with a focus on sugar. In addition to exploring the history, market, and consumption of sugar, the column will outline the steps involved in processing and production.. Food Manufacturing in the time of COVID-19 April 7.

Process flow sheets Sugar from sugar cane Production process with flowsheet

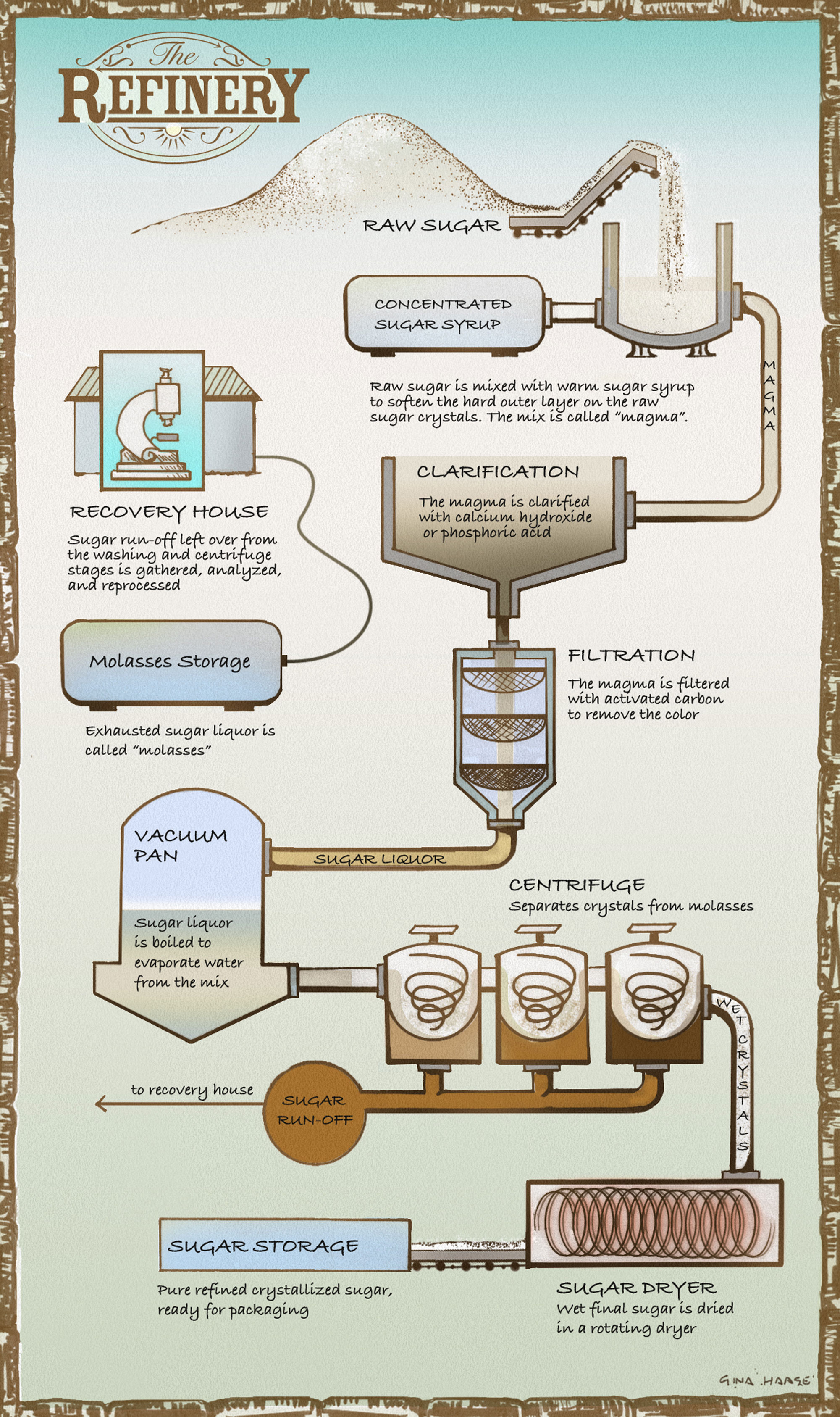

A simplified process flow diagram for refined sugar production is shown in Figure 9.10.1.1-2. Cane sugar is refined either at the same location where it was produced as part of an integrated facility or at separate raw sugar refineries. The initial step in cane sugar refining is washing the sugar, called affination,

Sugar Facts for Kids

Sugar beet is also one of the alternatives. The manufacturing process of sugar has evolved over the years, with new technology it has been made more efficient. But the essence of the process of juicing the sugar cane or beet and clarifying it before crystallization remains the same. Sugar manufacturing can be explained in the following steps.

The diagram shows the manufacturing process for making sugar from sugar cane 9IELTS

CLARIFICATION STEPS IN THE PHOSPHATATION PROCESS The process of floatation can be divided in three main steps:- Phosphateflocculation. Air floatation. Scumproduction. Phosphateflocculation: The objective of first step is to form a floccules that would occlude, adsorb and absorb the greatest possible portion of impurities.

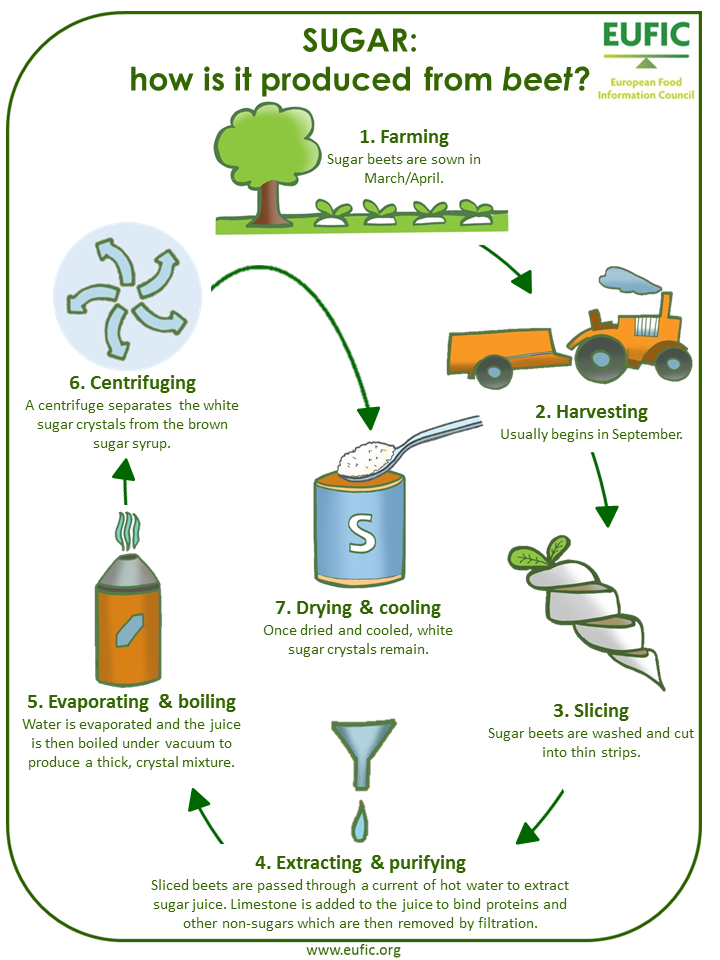

Sugar how is it produced from beet? (EUFIC)

Sugar Production from Sugar Cane The basic process Sugar cane must be crushed to extract the juice. The crushing process must break up the hard nodes of the cane and flatten the stems. The juice is collected, filtered and sometimes treated and then boiled to drive off the excess water. The dried cane residue (bagasse) is often used as

PPT “Sugar” PowerPoint Presentation, free download ID2625119

Chemistry of Saccharose (inversion, pol, purity, and reducing sugars) The main component of interest in sugarcane is sucrose. It is a disaccharide that results from the chemical bond between two monosaccharides: glucose and fructose (both hexose or sugars with six carbon atoms). The schematic chemical structures from the monosaccharides.

Sugar Production Flowsheet with GATE Questions YouTube

The Process of obtaining Raw Sugar Cane Preparation Once the sugarcane has been harvested and delivered to a sugar factory, the first step towards obtaining raw sugar crystals is to prepare the cane thoroughly by cutting and shredding the stalks in heavy preparation equipment so as to disintegrate the material and expose the sucrose-containing plant cells in the cane.

Purification of Sugar The Canadian Sugar Institute

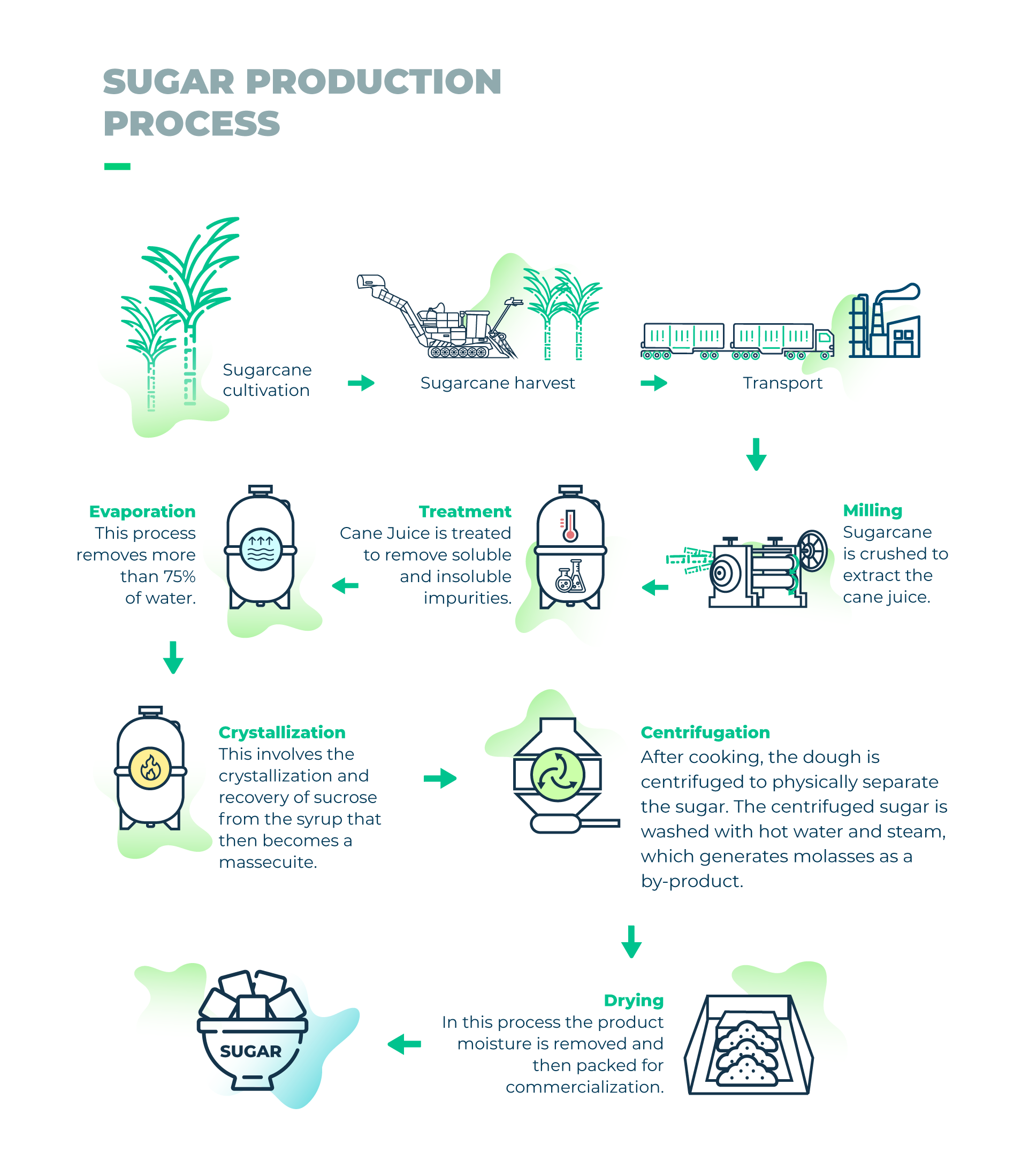

What is refined sugar. Refined Sugar is produced by sugar cane or beet via raw sugar. (i.e From sugar cane or beet, first produced raw sugar by ordinary process known as Defecation process. Then raw Sugar is following further process like melting, clarification and decolourization to produced refined sugar.)

Sugar A Practical Guide The Rum Reader

Sugar is produced in two principal ways, from beet or cane. In beet production sugar is extracted or leached from sliced sugar beets (cossettes), after which juice is purified through a series of milk of lime and CO 2 process steps. The filtered juice is evaporated (thickened) and sugar is crystallized from it.

A sugar production diagram Royalty Free Vector Image

Sugar manufacturing works broadly on a ratio of 7:1. We need to process about seven tonnes of cane to produce one tonne of raw sugar. This varies depending on the type of cane, the CCS (commercial cane sugar) content, the season and a host of other factors. The cane crushing season typically runs from June to November.

How Is Sugar Made? Sugar Information

The production of sugar cane can be broken down into 6 key steps: 1.How to Grow Sugar Cane 2.Harvesting Sugar Cane 3.Total recoverable sugar (TRS) 4.How to process sugar cane - Extraction - Clarification - Boiling - Crystallisation - Centrifuging 5.Raw Sugar 6.Refined Cane Sugar. How to grow sugar cane

Sugar Industry _A Process Process Control Overview Sugar industry, Process control, Technology

At the mill, sugar cane stalks are washed, cut and the shreds are pressed (1). This process releases juices, which are then clarified, concentrated, and crystalized. The remaining product is spun in a centrifuge, a machine that spins rapidly and separates out the sugar from the liquid. The raw sugar is then transported to a sugar refinery.

.